HiPer Checkup

HiPer Checkup is a comprehensive digital “health checkup” of real estate utility systems to reduce operating costs and improve operational service discipline

- Reduced energy consumption and costs for the operation of utility systems (HVAC, electricity, etc.)

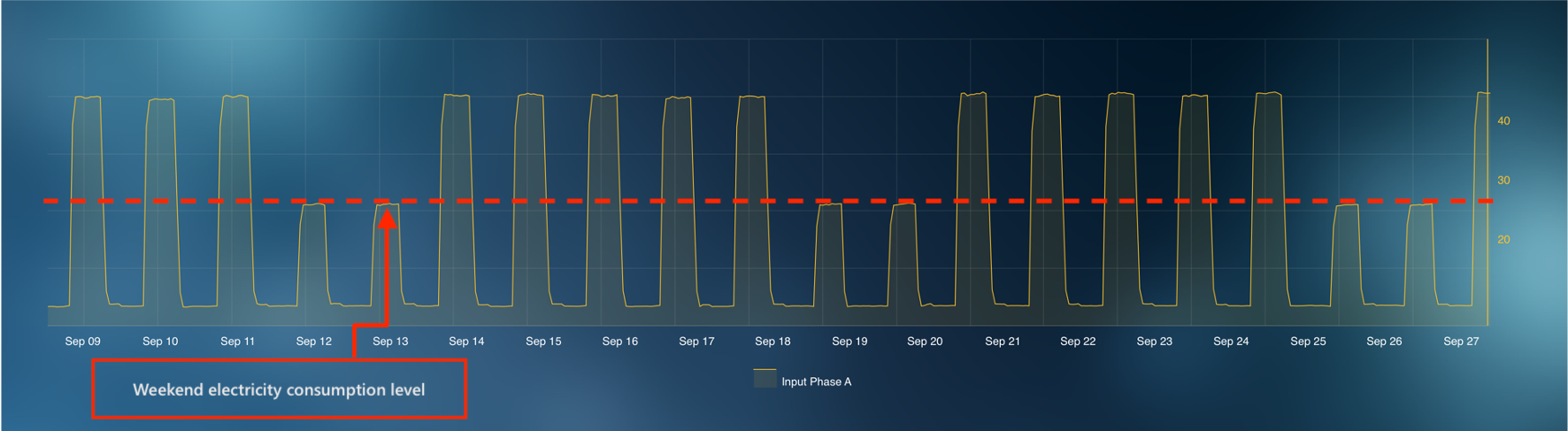

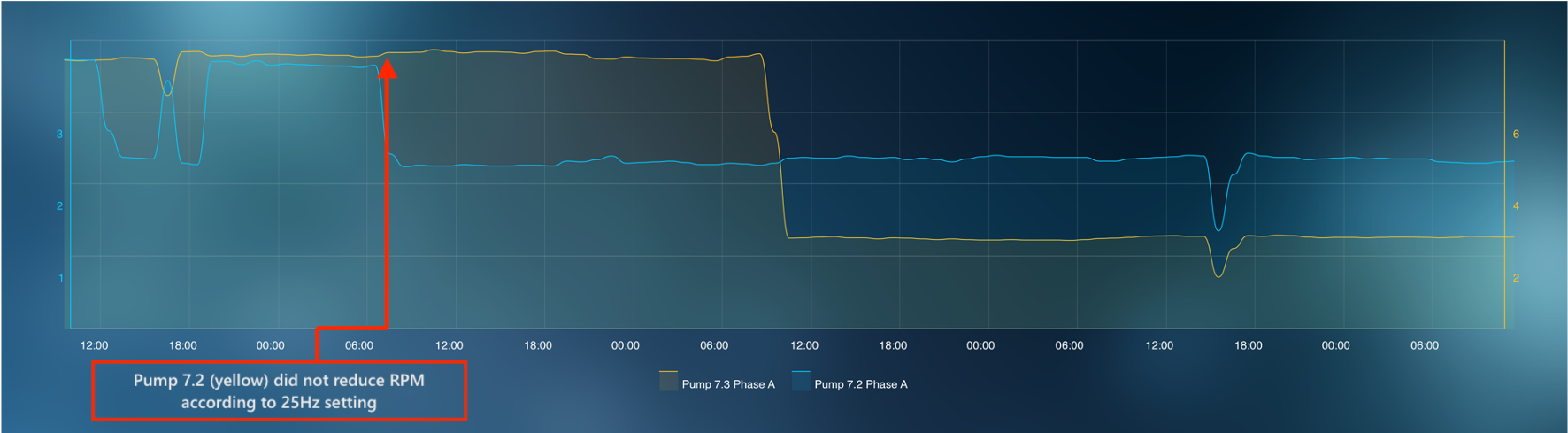

- Localization and analysis of deviations from normal operations

- Efficiency audit of operational processes and recommendations for optimization

- Discipline imrovement of personnel supporting utility systems

BENEFITS

PRECISE

Clear identification of "pain points" and checkup objectives

BIG DATA DRIVEN

Analytics and recommendations are formulated based on the collection of Big Data

FAST

In just five weeks from the start of the project, you’ll get detailed analytics and recommendations for improving operational efficiency

NONINTRUSIVE

Data collection doesn’t require intrusion or shutting down any systems

COST-EFFECTIVE

Lowest cost of digital utility systems analysis in the commercial real estate market

A COMPLETE DIGITAL

CHECKUP IN JUST 3 STEPS

Installing devices and collecting data

Diagnostic devices are installed on buildings’ utility systems (electricity and heat supply, air conditioning, ventilation), as well as devices to transmit the operational data

Diagnostics and analytics

Big Data on the functioning of utility systems is collected and displayed in real time. The data is analyzed, and any operational problems and their sources are detected

Recommendations

Data from utility systems is given more extensive analysis to determine cause-and-effect relationships in complex processes, then recommendations are given for improving the efficiency of operating procedures